The 2-Minute Rule for gearbox cvt

The 2-Minute Rule for gearbox cvt

Blog Article

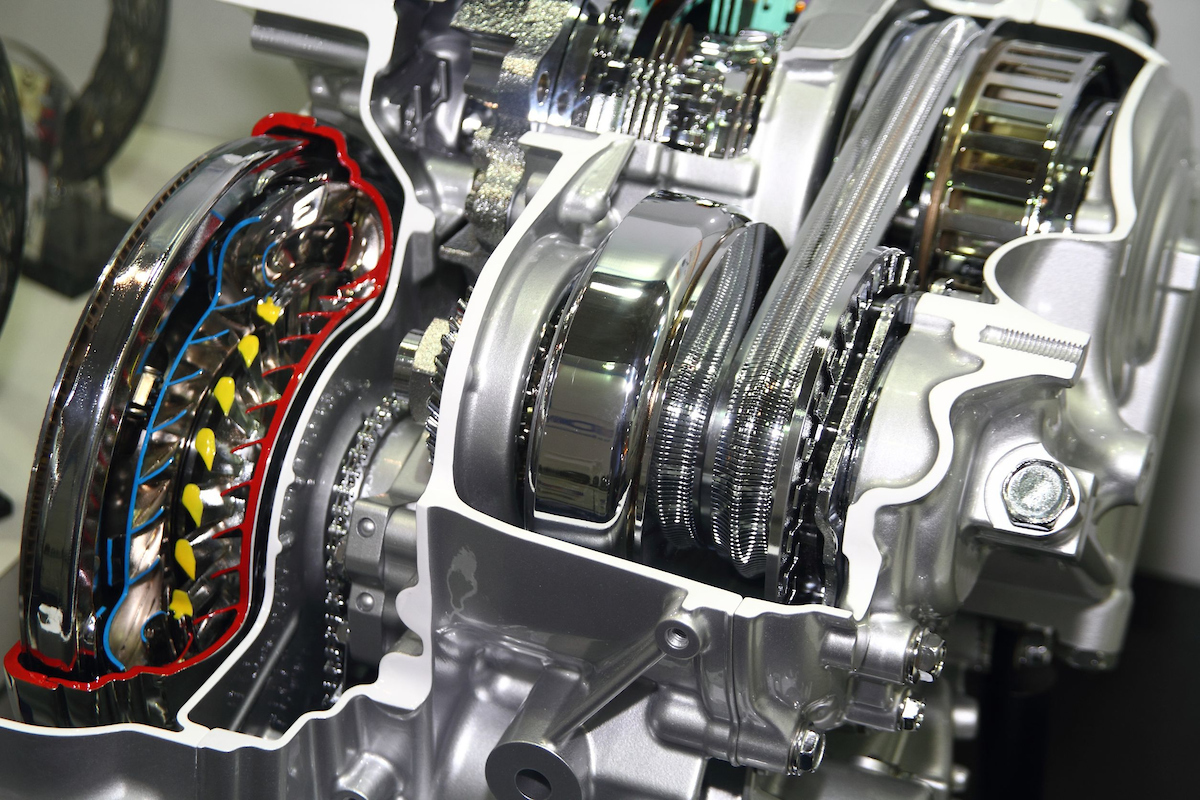

The commonest style of CVT makes use of a V-belt which operates involving two variable-diameter pulleys.[2] The pulleys encompass two cone-formed halves that go collectively and apart. The V-belt runs concerning both of these halves, Hence the effective diameter from the pulley is dependent on the distance between the two halves with the pulley.

Simple English explanation!! Anyone really should read this and try a minimum of several distinctive CVT’s prior to stating all are garbage.

Damaged or worn CVT belts: The purpose of the belt is always to transfer electricity with the motor on the transmission. When this part has any issue, it might cause shaking and shuddering.

In distinction, handful of hydrostatic transmission programs obtain in excess of about sixty five per cent performance. This is because of a combination of interior losses while in the pump and motor(s), and losses from the piping and valves.

Consequently these items need to be extremely sturdy in construction, generally causing large parts. Further body weight will be present in the oil reservoir and its oil load, in addition to the piping and valving.

CVT in a Claas Mercator Blend harvester. The pulley's effective diameter is altered by pushing the two conical discs both toward or away from each other.

Compact industrial motor vehicles for instance gentle tractors typically utilize them, and you see them on snowmobiles too. The Aussie-crafted Tomcar smaller off-road auto (pictured earlier mentioned) also utilises a CVT, and Nissan’s new Pathfinder is without doubt one of the much larger comfortable-roaders nevertheless it as well has a CVT at its coronary heart.

Transmission info lebih lanjut fluid is absolutely vital for trying to keep your automobile’s transmission working adequately. This specially formulated fluid lubricates the transmission’s…

Settlements and buybacks: In some instances, Nissan has presented settlements or buybacks to buyers who definitely have expert major problems with their CVT transmissions.

I'm the founder of Each day Motor vehicle Suggestions. I wrote articles or blog posts during the automotive field for more than a decade, published in United states of america and Europe. I love sharing my understanding and insights with fellow lovers. Join me on this journey as we examine the thrilling entire world of autos jointly! Check out all posts

Concurrently when this enter pulley(sheave) moves, feeding output pulley(sheave) also moves and comes closer into the mounted output pulley which subsequently shift the Component of v-shaped belt wrapped about the output pulleys in direction of the increased cross-sectional location of the output conical pulleys and wanted torque ratios is attained.

Ratcheting CVTs can transfer substantial torque since their static friction really will increase relative to torque throughput, so slippage is impossible in correctly built devices. Performance is mostly large because the majority of the dynamic friction is a result of really slight transitional clutch pace improvements.

I applied a drill press that labored on precisely the same principle. No halting the device to maneuver the belt to a unique pulley… turning the hand wheel on top of the push allowed infinitely variable chuck r.

when the auto demands speed ratios, the feeding conical pulley (sheave) around the input shaft moves towards the fastened pulley which in turn shifts the Element of v-shaped belt wrapped over the enter pulleys towards the increased cross-sectional A part of the conical enter pulleys.